What Is a Jet Engine? Evolution of Jet Engine

What Is a Jet

Engine? The Brayton Thermodynamic Cycle

Broadly speaking, jet engine are

internal combustion engines and considered a type of reaction engine, that

discharges a fast-moving jet of heated gas that generates thrust by jet

propulsion. The term jet engine typically refers to an internal combustion

air-breathing jet engine such as a turbojet, turbofan, ramjet, pulse jet, or

scramjet. Air-breathing jet engines typically feature a rotating air compressor

powered by a turbine, with the leftover power providing thrust through the

propelling nozzle. This process is known

as the Brayton thermodynamic cycle. Jet powered aircraft use such engines for

long-distance travel. Early jet aircraft used turbojet engines that were

relatively inefficient for subsonic flight. Most modern subsonic jet aircraft

use high-bypass turbofan engines with higher speed and greater fuel efficiency

than piston and propeller aeroengines over long distances.

The thrust of a typical jetliner

engine went from 5,000 lbf (22 kN) (de Havilland Ghost turbojet) in the 1950s

to 115,000 lbf (510 kN) (General Electric GE90 turbofan) in the 1990s, and

their reliability went from 40 in-flight shutdowns per 100,000 engine flight

hours to less than 1 per 100,000 in the late 1990s. The principle of the jet

engine is not new; however, the technical advances necessary to make the idea

work did not come to fruition until the 20th century. A rudimentary

demonstration of jet power dates back to the aeolipile, a device described by

Hero of Alexandria in 1st-century Egypt. This device directed steam power

through two nozzles to cause a sphere to spin rapidly on its axis. It was seen

as a curiosity. Meanwhile, practical applications of the turbine can be seen in

the water wheel and the windmill. Historians have further traced the

theoretical origin of the principles of jet engines to traditional Chinese

firework and rocket propulsion systems. Such devices' use for flight is documented

in the story of Ottoman soldier Lagâri Hasan Çelebi, who reportedly achieved

flight using a cone-shaped rocket in 1633.

Evolution of Jet

Engine and Early Experiments in Jet Propulsion

The earliest attempts at

airbreathing jet engines were hybrid designs in which an external power source

first compressed air, which was then mixed with fuel and burned for jet thrust.

The Italian Caproni Campini N.1, and the Japanese Tsu-11 engine intended to

power Ohka kamikaze planes towards the end of World War II were unsuccessful.

Even before the start of World War II, engineers were beginning to realize that

engines driving propellers were approaching limits due to issues related to

propeller efficiency, which declined as blade tips approached the speed of

sound. If aircraft performance were to increase beyond such a barrier, a

different propulsion mechanism was necessary. This was the motivation behind

the development of the gas turbine engine, the most common form of jet engine.

The key to a practical jet engine

was the gas turbine, extracting power from the engine itself to drive the

compressor. The gas turbine was not a new idea: the patent for a stationary

turbine was granted to John Barber in England in 1791. The first gas turbine to

successfully run self-sustaining was built in 1903 by Norwegian engineer

Ægidius Elling. Such engines did not reach manufacture due to issues of safety,

reliability, weight and, especially, sustained operation. First patent for

using a gas turbine to power an aircraft was filed in 1921 by Maxime Guillaume.

His engine was an axial-flow turbojet, but was never constructed, as it would

have required considerable advances over the state of the art in compressors.

Alan Arnold Griffith published An Aerodynamic Theory of Turbine Design in 1926

leading to experimental work at the RAE. Whittle W.2/700 engine flew in the

Gloster E.28/39, the first British aircraft to fly with a turbojet engine, and

the Gloster Meteor

Contribution of Frank

Whittle & Virgilio Leret Ruiz

In 1928, RAF College Cranwell

cadet Frank Whittle formally submitted his ideas for a turbojet to his superior

and his first patent was granted in 1932. The patent showed a two-stage axial

compressor feeding a single-sided centrifugal compressor. Practical axial

compressors were made possible by ideas from A.A.Griffith in a seminal paper in

1926 ("An Aerodynamic Theory of Turbine Design"). Whittle would later

concentrate on the simpler centrifugal compressor only. Whittle was unable to

interest the government in his invention, and development continued at a slow

pace.

In Spain, pilot and engineer

Virgilio Leret Ruiz was granted a patent for a jet engine design in March 1935.

Republican president Manuel Azaña arranged for initial construction at the

Hispano-Suiza aircraft factory in Madrid in 1936, but Leret was executed months

later by Francoist Moroccan troops after unsuccessfully defending his seaplane

base on the first days of the Spanish Civil War. His plans, hidden from

Francoists, were secretly given to the British embassy in Madrid a few years

later by his wife, Carlota O'Neill, upon her release from prison.

Hans von Ohain

& German Jet Engine

In 1935, Hans von Ohain started

work on a similar design to Whittle's in Germany, both compressor and turbine

being radial, on opposite sides of the same disc, initially unaware of

Whittle's work. Von Ohain's first device was strictly experimental and could

run only under external power, but he was able to demonstrate the basic

concept. Ohain was then introduced to Ernst Heinkel, one of the largest aircraft

industrialists of the day, who immediately saw the promise of the design.

Heinkel had recently purchased the Hirth engine company, and Ohain and his

master machinist Max Hahn were set up there as a new division of the Hirth

company. They had their first HeS 1 centrifugal engine running by September

1937. Unlike Whittle's design, Ohain used hydrogen as fuel, supplied under

external pressure. Their subsequent designs culminated in the gasoline-fuelled

HeS 3 of 5 kN (1,100 lbf), which was fitted to Heinkel's simple and compact He

178 airframe and flown by Erich Warsitz in the early morning of August 27, 1939,

from Rostock-Marienehe aerodrome, an impressively short time for development.

The He 178 was the world's first jet plane. Heinkel applied for a US patent

covering the Aircraft Power Plant by Hans Joachim Pabst von Ohain on May 31,

1939; patent number US2256198, with M Hahn referenced as inventor. Von Ohain's

design, an axial-flow engine, as opposed to Whittle's centrifugal flow engine,

was eventually adopted by most manufacturers by the 1950s.

The Gas Turbine

Era and Axial Compressor Breakthrough

Austrian Anselm Franz of Junkers'

engine division (Junkers Motoren or "Jumo") introduced the axial-flow

compressor in their jet engine. Jumo was assigned the next engine number in the

RLM 109-0xx numbering sequence for gas turbine aircraft powerplants,

"004", and the result was the Jumo 004 engine. After many lesser

technical difficulties were solved, mass production of this engine started in

1944 as a powerplant for the world's first jet-fighter aircraft, the

Messerschmitt Me 262 (and later the world's first jet-bomber aircraft, the

Arado Ar 234). A variety of reasons conspired to delay the engine's

availability, causing the fighter to arrive too late to improve Germany's

position in World War II, however this was the first jet engine to be used in

service.

Meanwhile, in Britain the Gloster

E28/39 had its maiden flight on 15 May 1941 and the Gloster Meteor finally

entered service with the RAF in July 1944. The Gloster Meteor was the first

British jet fighter and the Allies' only jet aircraft to achieve combat

operations during World War II. These were powered by turbojet engines from

Power Jets Ltd., set up by Frank Whittle. The first two operational turbojet

aircraft, the Messerschmitt Me 262 and then the Gloster Meteor entered service

within three months of each other in 1944; the Me 262 in April and the Gloster

Meteor in July. The Meteor only saw around 15 aircraft enter World War II

action, while up to 1400 Me 262 were produced, with 300 entering combat,

delivering the first ground attacks and air combat victories of jet planes.

By the 1950s, the jet engine was

almost universal in combat aircraft, with the exception of cargo, liaison and

other specialty types. By this point, some of the British designs were already

cleared for civilian use, and had appeared on early models like the de

Havilland Comet and Avro Canada Jetliner. By the 1960s, all large civilian

aircraft were also jet powered, leaving the piston engine in low-cost niche

roles such as cargo flights. The efficiency of turbojet engines was still

rather worse than piston engines, but by the 1970s, with the advent of

high-bypass turbofan jet engines (an innovation not foreseen by the early

commentators such as Edgar Buckingham, at high speeds and high altitudes that

seemed absurd to them), fuel efficiency was about the same as the best piston

and propeller engines.

Uses

By the 1950s, the jet engine was almost universal in combat aircraft, with

the exception of cargo, liaison and other specialty types. By this point, some

of the British designs were already cleared for civilian use, and had appeared

on early models like the de Havilland Comet and Avro Canada Jetliner. By the

1960s, all large civilian aircraft were also jet powered, leaving the piston

engine in low-cost niche roles such as cargo flights. The efficiency of

turbojet engines was still rather worse than piston engines, but by the 1970s,

with the advent of high-bypass turbofan jet engines (an innovation not foreseen

by the early commentators such as Edgar Buckingham, at high speeds and high

altitudes that seemed absurd to them), fuel efficiency was about the same as

the best piston and propeller engines.

Jet engine designs are frequently

modified for non-aircraft applications, as industrial gas turbines or marine

powerplants. These are used in electrical power generation, for powering water,

natural gas, or oil pumps, and providing propulsion for ships and locomotives.

Industrial gas turbines can create up to 50,000 shaft horsepower. Many of these

engines are derived from older military turbojets such as the Pratt &

Whitney J57 and J75 models. There is also a derivative of the P&W JT8D

low-bypass turbofan that creates up to 35,000 horsepower (HP). Jet engines are

also sometimes developed into, or share certain components such as engine

cores, with turboshaft and turboprop engines, which are forms of gas turbine

engines that are typically used to power helicopters and some propeller-driven

aircraft.

Types of Jet

Engine

Airbreathing

Commonly aircraft are propelled

by airbreathing jet engines. Most airbreathing jet engines that are in use

are turbofan jet engines, which give good efficiency at speeds just

below the speed of sound.

Turbojet

A turbojet engine is

a gas turbine engine that works by compressing air with an inlet and

a compressor (axial, centrifugal, or both), mixing fuel with the

compressed air, burning the mixture in the combustor, and then passing the

hot, high pressure air through a turbine and a nozzle. The

compressor is powered by the turbine, which extracts energy from the expanding

gas passing through it. The engine converts internal energy in the fuel to

increased momentum of the gas flowing through the engine, producing thrust. All

the air entering the compressor is passed through the combustor, and turbine,

unlike the turbofan engine described below.

Turbofan

Turbofans differ from

turbojets in that they have an additional fan at the front of the engine, which

accelerates air in a duct bypassing the core gas turbine engine. Turbofans are

the dominant engine type for medium and long-range airliners. Turbofans

are usually more efficient than turbojets at subsonic speeds, but at high

speeds their large frontal area generates more drag. Therefore, in

supersonic flight, and in military and other aircraft where other

considerations have a higher priority than fuel efficiency, fans tend to be

smaller or absent.

Because of these distinctions,

turbofan engine designs are often categorized as low-bypass or high-bypass,

depending upon the amount of air which bypasses the core of the engine.

Low-bypass turbofans have a bypass ratio of around 2:1 or less.

Propfan

A propfan engine is a

type of airbreathing jet engine which combines aspects of turboprop and turbofan.

Its design consists of a central gas turbine which drives open-air contra-rotating

propellers. Unlike turboprop engines, in which the propeller and the engine are

considered two separate products, the propfan’s gas generator and its

unshrouded propeller module are heavily integrated and are considered to be a

single product. [Additionally, the propfan’s short, heavily

twisted variable pitch blades closely remember the ducted fan blades

of turbofan engines. Propfans are designed to offer the speed and performance

of turbofan engines with fuel efficiency of turboprops. However, due to low

fuel costs and high cabin noise, early propfan projects were abandoned. Very

few aircraft have flown with propfans, with the Antonov An-70 being

the first and only aircraft to fly while being powered solely by propfan

engines.

Advanced Technology

Engine (ATE)

ATE refers to the modern

generation of jet engines. The principle is that a turbine engine will

function more efficiently if the various sets of turbines can revolve at their

individual optimum speeds, instead of at the same speed. The true advanced

technology engine has a triple spool, meaning that instead of having a single

drive shaft, there are three, in order that the three sets of blades may

revolve at different speeds. An interim state is a twin-spool engine, allowing

only two different speeds for the turbines.

Ram Compression

Ram compression jet engines are

airbreathing engines similar to gas turbine engines in so far as they both use

the Brayton cycle. Gas turbine and ram compression engines differ,

however, in how they compress the incoming airflow. Whereas gas turbine engines

use axial or centrifugal compressors to compress incoming air, ram engines rely

only on air compressed in the inlet or diffuser. A ram engine thus

requires a substantial initial forward airspeed before it can function. Ramjets

are considered the simplest type of air breathing jet engine because they have

no moving parts in the engine proper, only in the accessories. Scramjets differ mainly in the fact that the air does not

slow to subsonic speeds. Rather, they use supersonic combustion. They are

efficient at even higher speed. Very few have been built or flown.

Non-Continuous

Combustion

|

Type |

Description |

Advantages |

Disadvantages |

|

Motorjet |

Works like a turbojet

but a piston engine drives the compressor instead of a turbine. |

Higher exhaust

velocity than a propeller, offering better thrust at high speed |

Heavy, inefficient and

underpowered. Example: Caproni Campini N.1. |

|

Pulsejet |

Air is compressed and

combusted intermittently instead of continuously. Some designs use valves. |

Very simple design,

used for the V-1 flying bomb and more recently on model aircraft |

Noisy, inefficient

(low compression ratio), works poorly on a large scale, valves on valved

designs wear out quickly |

|

Pulse detonation

engine |

Similar to a pulsejet,

but combustion occurs as a detonation instead of a deflagration,

may or may not need valves |

Maximum theoretical

engine efficiency |

Extremely noisy, parts

subject to extreme mechanical fatigue, hard to start detonation, not

practical for current use |

Other Types of Jet

Propulsion

Rocket

By the 1950s, the jet engine was

almost universal in combat aircraft, with the exception of cargo, liaison and

other specialty types. By this point, some of the British designs were already

cleared for civilian use, and had appeared on early models like the de

Havilland Comet and Avro Canada Jetliner. By the 1960s, all large civilian

aircraft were also jet powered, leaving the piston engine in low-cost niche

roles such as cargo flights. The efficiency of turbojet engines was still

rather worse than piston engines, but by the 1970s, with the advent of

high-bypass turbofan jet engines (an innovation not foreseen by the early

commentators such as Edgar Buckingham, at high speeds and high altitudes that

seemed absurd to them), fuel efficiency was about the same as the best piston

and propeller engines.

Jet engine designs are frequently

modified for non-aircraft applications, as industrial gas turbines or marine

powerplants. These are used in electrical power generation, for powering water,

natural gas, or oil pumps, and providing propulsion for ships and locomotives.

Industrial gas turbines can create up to 50,000 shaft horsepower. Many of these

engines are derived from older military turbojets such as the Pratt &

Whitney J57 and J75 models. There is also a derivative of the P&W JT8D

low-bypass turbofan that creates up to 35,000 horsepower (HP). Jet engines are

also sometimes developed into, or share certain components such as engine

cores, with turboshaft and turboprop engines, which are forms of gas turbine

engines that are typically used to power helicopters and some propeller-driven

aircraft.

|

Type |

Description |

Advantages |

Disadvantages |

|

Rocket |

Carries all

propellants and oxidants on board, emits jet for propulsion |

Very few moving parts.

Mach 0 to Mach 25+; efficient at very high speed (> Mach 5.0 or so).

Thrust/weight ratio over 100. No complex air inlet. High compression ratio.

Very high-speed (hypersonic) exhaust. Good cost/thrust ratio. Fairly easy to

test. Works in a vacuum; indeed, works best outside the atmosphere, which is

kinder on vehicle structure at high speed. Fairly small surface area to keep

cool, and no turbine in hot exhaust stream. Very high-temperature combustion

and high expansion-ratio nozzle gives very high efficiency, at very high

speeds. |

Needs lots of

propellant. Very low specific impulse – typically 100–450 seconds.

Extreme thermal stresses of combustion chamber can make reuse harder.

Typically requires carrying oxidizer on-board which increases risks.

Extraordinarily noisy. |

Hybrid

Combined-cycle engines

simultaneously use two or more different principles of jet propulsion.

|

Type |

Description |

Advantages |

Disadvantages |

|

Turbo |

A turbojet where an

additional oxidizer such as oxygen is added to the

airstream to increase maximum altitude |

Very close to existing

designs, operates in very high altitude, wide range of altitude and airspeed |

Airspeed limited to

same range as turbojet engine, carrying oxidizer like LOX can be

dangerous. Much heavier than simple rockets. |

|

Air-augmented rocket |

Essentially a ramjet

where intake air is compressed and burnt with the exhaust from a rocket |

Mach 0 to Mach 4.5+

(can also run exoatmospheric), good efficiency at Mach 2 to 4 |

Similar efficiency to

rockets at low speed or exoatmospheric, inlet difficulties, a relatively

undeveloped and unexplored type, cooling difficulties, very noisy,

thrust/weight ratio is similar to ramjets. |

|

Precooled jets / LACE |

Intake air is chilled

to very low temperatures at inlet in a heat exchanger before passing through

a ramjet and/or turbojet and/or rocket engine. |

Easily tested on

ground. Very high thrust/weight ratios are possible (~14) together with good

fuel efficiency over a wide range of airspeeds, Mach 0–5.5+; this combination

of efficiencies may permit launching to orbit, single stage, or very rapid,

very long distance intercontinental travel. |

Exists only at the lab

prototyping stage. Examples include RB545, Reaction Engines SABRE, ATREX.

Requires liquid hydrogen fuel which has very low density and requires heavily

insulated tankage. |

Water Jet

A water jet, or pump-jet, is a

marine propulsion system that uses a jet of water. The mechanical arrangement

may be a ducted propeller with nozzle, or a centrifugal compressor and nozzle.

The pump-jet must be driven by a separate engine such as a Diesel or gas

turbine.

|

Type |

Description |

Advantages |

Disadvantages |

|

Water jet |

For propelling water

rockets and jetboats; squirts water out the back through a nozzle |

In boats, can run in

shallow water, high acceleration, no risk of engine overload (unlike

propellers), less noise and vibration, highly maneuverable at all boat

speeds, high speed efficiency, less vulnerable to damage from debris, very

reliable, more load flexibility, less harmful to wildlife |

Can be less efficient

than a propeller at low speed, more expensive, higher weight in boat due to

entrained water, will not perform well if boat is heavier than the jet is

sized for |

All jet engines are reaction

engines that generate thrust by emitting a jet of fluid rearwards at

relatively high speed. The forces on the inside of the engine needed to create

this jet give a strong thrust on the engine which pushes the craft forwards. Jet

engines make their jet from propellant stored in tanks that are attached to the

engine (as in a 'rocket') as well as in duct engines (those

commonly used on aircraft) by ingesting an external fluid (very typically air)

and expelling it at higher speed.

Propelling Nozzle

A propelling nozzle produces a

high velocity exhaust jet. Propelling nozzles turn internal and pressure

energy into high velocity kinetic energy. The total

pressure and temperature don't change through the nozzle but their static

values drop as the gas speeds up. The velocity of the air entering the nozzle

is low, about Mach 0.4, a prerequisite for minimizing pressure losses in the

duct leading to the nozzle. The temperature entering the nozzle may be as low

as sea level ambient for a fan nozzle in the cold air at cruise altitudes. It

may be as high as the 1000 Kelvin exhaust gas temperature for a

supersonic afterburning engine or 2200 K with afterburner lit. The

pressure entering the nozzle may vary from 1.5 times the pressure outside the

nozzle, for a single stage fan, to 30 times for the fastest manned aircraft at

Mach 3+. Convergent nozzles are only able to

accelerate the gas up to local sonic (Mach 1) conditions. To reach high flight

speeds, even greater exhaust velocities are required, and so a convergent-divergent

nozzle is needed on high-speed aircraft.

The engine thrust is highest if the static pressure of the gas reaches the ambient value as it leaves the nozzle. This only happens if the nozzle exit area is the correct value for the nozzle pressure ratio (npr). Since the npr changes with engine thrust setting and flight speed this is seldom the case. Also at supersonic speeds the divergent area is less than required to give complete internal expansion to ambient pressure as a trade-off with external body drag. Whitford gives the F-16 as an example. Other underexpanded examples were the XB-70 and SR-71. The nozzle size, together with the area of the turbine nozzles, determines the operating pressure of the compressor.

Thrust

A jet engine at rest, as on a

test stand, sucks in fuel and generates thrust. How well it does this is judged

by how much fuel it uses and what force is required to restrain it. This is a

measure of its efficiency. If something deteriorates inside the engine (known

as performance deterioration) it will be less efficient and this will show when

the fuel produces less thrust. If a change is made to an internal part which

allows the air/combustion gases to flow more smoothly the engine will be more

efficient and use less fuel. A standard definition is used to assess how

different things change engine efficiency and also to allow comparisons to be

made between different engines. This definition is called specific fuel

consumption, or how much fuel is needed to produce one unit of thrust. For

example, it will be known for a particular engine design that if some bumps in

a bypass duct are smoothed out the air will flow more smoothly giving a

pressure loss reduction of x% and y% less fuel will be needed to get the

take-off thrust, for example. This understanding comes under the engineering

discipline Jet engine performance. How efficiency is affected by forward

speed and by supplying energy to aircraft systems is mentioned later.

Efficiency

The efficiency of the engine is

controlled primarily by the operating conditions inside the engine which are

the pressure produced by the compressor and the temperature of the combustion

gases at the first set of rotating turbine blades. The pressure is the highest

air pressure in the engine. The turbine rotor temperature is not the highest in

the engine but is the highest at which energy transfer takes place (higher

temperatures occur in the combustor). The above pressure and temperature are

shown on a Thermodynamic cycle diagram. The efficiency is further

modified by how smoothly the air and the combustion gases flow through the

engine, how well the flow is aligned (known as incidence angle) with the moving

and stationary passages in the compressors and turbines. Non-optimum angles, as

well as non-optimum passage and blade shapes can cause thickening and

separation of Boundary layers and formation of Shock waves.

It is important to slow the flow

(lower speed means less pressure losses or Pressure drop) when it travels

through ducts connecting the different parts. How well the individual

components contribute to turning fuel into thrust is quantified by measures

like efficiencies for the compressors, turbines and combustor and pressure

losses for the ducts. These are shown as lines on a Thermodynamic cycle diagram.

The engine efficiency, or thermal efficiency is

dependent on the Thermodynamic cycle parameters, maximum pressure and

temperature, and on component efficiencies, and duct pressure losses. The engine

needs compressed air for itself just to run successfully. This air comes from

its own compressor and is called secondary air. It does not contribute to

making thrust so makes the engine less efficient.

It is used to preserve the

mechanical integrity of the engine, to stop parts overheating and to prevent

oil escaping from bearings for example. Only some of this air taken from the

compressors returns to the turbine flow to contribute to thrust production. Any

reduction in the amount needed improves the engine efficiency. Again, it will

be known for a particular engine design that a reduced requirement for cooling

flow of x% will reduce the specific fuel consumption by y%. In other

words, less fuel will be required to give take-off thrust, for example. The

engine is more efficient.

All of the above considerations are basic to the engine running on its own and, at the same time, doing nothing useful, i.e. it is not moving an aircraft or supplying energy for the aircraft's electrical, hydraulic and air systems. In the aircraft the engine gives away some of its thrust-producing potential, or fuel, to power these systems. These requirements, which cause installation losses, reduce its efficiency. It is using some fuel that does not contribute to the engine's thrust. Finally, when the aircraft is flying the propelling jet itself contains wasted kinetic energy after it has left the engine.

This is quantified by the

term propulsive, or Froude, efficiencyand may be reduced by

redesigning the engine to give it bypass flow and a lower speed for the

propelling jet, for example as a turboprop or turbofan engine. At the same time

forward speed increases the by

increasing the overall pressure ratio.

Overall Pressure

Ratio and Thermodynamic Cycle

The overall efficiency of the

engine at flight speed is defined as.The

at flight speed depends on

how well the intake compresses the air before it is handed over to the engine

compressors. The intake compression ratio, which can be as high as 32:1 at Mach

3, adds to that of the engine compressor to give the Overall pressure ratio and for the Thermodynamic cycle. How

well it does this is defined by its pressure recovery or measure of the losses

in the intake. Mach 3 manned flight has provided an interesting illustration of

how these losses can increase dramatically in an instant.

The North American XB-70

Valkyrie and Lockheed SR-71 Blackbird at Mach 3 each had

pressure recoveries of about 0.8, due to relatively low losses during the

compression process, i.e. through systems of multiple shocks. During an

'unstart' the efficient shock system would be replaced by a very inefficient

single shock beyond the inlet and an intake pressure recovery of about 0.3 and

a correspondingly low-pressure ratio. The propelling nozzle at speeds above

about Mach 2 usually has extra internal thrust losses because the exit area is

not big enough as a trade-off with external afterbody drag.

Types of Efficiency

Although a bypass engine improves

propulsive efficiency it incurs losses of its own inside the engine itself.

Machinery has to be added to transfer energy from the gas generator to a bypass

airflow. The low loss from the propelling nozzle of a turbojet is added to with

extra losses due to inefficiencies in the added turbine and fan. These may be

included in a transmission, or transfer, efficiency. However, these losses are more

than made up by the improvement in propulsive

efficiency. There are also extra pressure losses in the bypass duct and an

extra propelling nozzle.

Dependence of propulsion

efficiency (η) upon the vehicle speed/exhaust velocity ratio (v/ve)

for air-breathing jet and rocket engines.

The energy efficiency of

jet engines installed in vehicles has two main components:

- propulsive efficiency :

how much of the energy of the jet ends up in the vehicle body rather than

being carried away as kinetic energy of the jet.

- cycle efficiency :

how efficiently the engine can accelerate the jet

Even though overall energy

efficiencyis:

For all

jet engines the propulsive efficiency is highest as the

exhaust jet velocity gets closer to the vehicle speed as this gives the

smallest residual kinetic energy. For an airbreathing engine an exhaust

velocity equal to the vehicle velocityor a equal to one, gives zero thrust

with no net momentum change. The formula for air-breathing engines moving at

speed

with an exhaust

velocity

, and neglecting fuel flow, is

and for a rocket is

.

In addition to propulsive efficiency, another factor is cycle efficiency; a jet engine is a form of heat engine. Heat engine efficiency is determined by the ratio of temperatures reached in the engine to that exhausted at the nozzle. This has improved constantly over time as new materials have been introduced to allow higher maximum cycle temperatures. For example, composite materials, combining metals with ceramics, have been developed for HP turbine blades, which run at the maximum cycle temperature. The efficiency is also limited by the overall pressure ratio that can be achieved. Cycle efficiency is highest in rocket engines (~60+%), as they can achieve extremely high combustion temperatures. Cycle efficiency in turbojet and similar is nearer to 30%, due to much lower peak cycle temperatures.

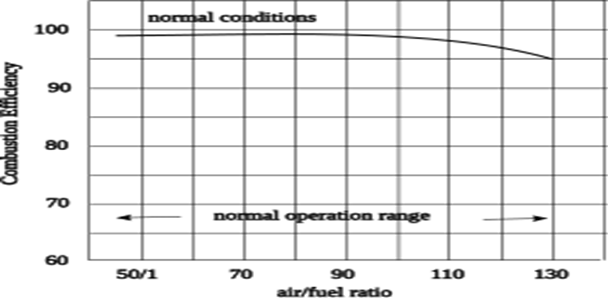

Typical combustion efficiency of

an aircraft gas turbine over the operational range. Typical combustion stability limits of an aircraft gas turbine. The

combustion efficiency of most aircraft gas turbine engines at sea level takeoff

conditions is almost 100%. It decreases nonlinearly to 98% at altitude cruise

conditions. Air-fuel ratio ranges from 50:1 to 130:1. For any type of

combustion chamber there is a rich and weak limit to

the air-fuel ratio, beyond which the flame is extinguished. The range of

air-fuel ratio between the rich and weak limits is reduced with an increase of

air velocity. If the increasing air mass flow reduces the fuel ratio below certain

value, flame extinction occurs. Specific impulse as a function of speed

for different jet types with kerosene fuel (hydrogen Isp would

be about twice as high). Although efficiency plummets with speed, greater

distances are covered. Efficiency per unit distance (per km or mile) is roughly

independent of speed for jet engines as a group; however, airframes become

inefficient at supersonic speeds.

Consumption of Fuel Or Propellant

A closely related (but different)

concept to energy efficiency is the rate of consumption of propellant mass.

Propellant consumption in jet engines is measured by specific fuel

consumption, specific impulse, or effective exhaust velocity.

They all measure the same thing. Specific impulse and effective exhaust

velocity are strictly proportional, whereas specific fuel consumption is

inversely proportional to the others. For air-breathing engines such as

turbojets, energy efficiency and propellant (fuel) efficiency are much the same

thing, since the propellant is a fuel and the source of energy. In rocketry,

the propellant is also the exhaust, and this means that a high energy

propellant gives better propellant efficiency but can in some cases actually

give lower energy efficiency. It can be seen in the table

(just below) that the subsonic turbofans such as General Electric's CF6

turbofan use a lot less fuel to generate thrust for a second than did the Concorde's Rolls-Royce/Snecma

Olympus 593 turbojet. However, since energy is measured by force times

distance and the distance per second was greater for the Concorde, the actual

power generated by the engine for the same amount of fuel was higher for the

Concorde at Mach 2 than the CF6. Thus, the Concorde's engines were more

efficient in terms of energy per distance traveled.

Thrust-To-Weight

Ratio

The thrust-to-weight ratio of jet

engines with similar configurations varies with scale, but is mostly a function

of engine construction technology. For a given engine, the lighter the engine,

the better the thrust-to-weight is, the less fuel is used to compensate for

drag due to the lift needed to carry the engine weight, or to accelerate the

mass of the engine. As can be seen in the following table, rocket engines

generally achieve much higher thrust-to-weight ratios than duct engines such

as turbojet and turbofan engines.

This is primarily because rockets

almost universally use dense liquid or solid reaction mass which gives a much

smaller volume and hence the pressurization system that supplies the nozzle is

much smaller and lighter for the same performance. Duct engines have to deal

with air which is two to three orders of magnitude less dense and this gives

pressures over much larger areas, which in turn results in more engineering

materials being needed to hold the engine together and for the air compressor.

Comparison of Types

Propeller engines handle larger

air mass flows, and give them smaller acceleration, than jet engines. Since the

increase in air speed is small, at high flight speeds the thrust available to

propeller-driven aeroplanes is small. However, at low speeds, these engines

benefit from relatively high propulsive efficiency. On the other hand,

turbojets accelerate a much smaller mass flow of intake air and burned fuel,

but they then reject it at very high speed. When a de Laval nozzle is

used to accelerate a hot engine exhaust, the outlet velocity may be

locally supersonic.

Turbojets are

particularly suitable for aircraft travelling at very high speeds. Turbofans

have a mixed exhaust consisting of the bypass air and the hot combustion

product gas from the core engine. The amount of air that bypasses the core

engine compared to the amount flowing into the engine determines what is called

a turbofan's bypass ratio (BPR). While a turbojet engine uses all of the

engine's output to produce thrust in the form of a hot high-velocity exhaust

gas jet, a turbofan's cool low-velocity bypass air yields between 30% and 70%

of the total thrust produced by a turbofan system. The net thrust (FN)

generated by a turbofan can also be expanded as:where:

|

ṁ e |

= the mass rate of hot combustion exhaust flow from the

core engine |

|

ṁo |

= the mass rate of total air flow entering the turbofan

= ṁc + ṁf |

|

ṁc |

= the mass rate of intake air that flows to the core engine |

|

ṁf |

= the mass rate of intake air that bypasses the core engine |

|

vf |

= the velocity of the air flow bypassed around the core

engine |

|

vhe |

= the velocity of the hot exhaust gas from the core engine |

|

vo |

= the velocity of the total air intake = the true airspeed

of the aircraft |

|

BPR |

= Bypass Ratio |

Rocket engines have

extremely high exhaust velocity and thus are best suited for high speeds (hypersonic)

and great altitudes. At any given throttle, the thrust and efficiency of a

rocket motor improves slightly with increasing altitude (because the

back-pressure falls thus increasing net thrust at the nozzle exit plane),

whereas with a turbojet (or turbofan) the falling density of the air entering

the intake (and the hot gases leaving the nozzle) causes the net thrust to

decrease with increasing altitude. Rocket engines are more efficient than even

scramjets above roughly Mach 15.

Altitude and Speed

With the exception of scramjets,

jet engines, deprived of their inlet systems can only accept air at around half

the speed of sound. The inlet system's job for transonic and supersonic

aircraft is to slow the air and perform some of the compression. The limit on

maximum altitude for engines is set by flammability – at very high altitudes

the air becomes too thin to burn, or after compression, too hot. For turbojet

engines altitudes of about 40 km appear to be possible, whereas for ramjet

engines 55 km may be achievable. Scramjets may theoretically manage

75 km. Rocket engines of course have no upper limit. At more modest

altitudes, flying faster compresses the air at the front of the engine,

and this greatly heats the air. The upper limit is usually thought to be about

Mach 5–8, as above about Mach 5.5, the atmospheric nitrogen tends to react due

to the high temperatures at the inlet and this consumes significant energy. The

exception to this is scramjets which may be able to achieve about Mach 15 or

more, as they avoid slowing the air, and rockets again have no particular speed

limit.

Noise

The noise emitted by a jet engine

has many sources. These include, in the case of gas turbine engines, the fan,

compressor, combustor, turbine and propelling jet/s. The

propelling jet produces jet noise which is caused by the violent mixing action

of the high-speed jet with the surrounding air. In the subsonic case the noise

is produced by eddies and in the supersonic case by Mach waves. The

sound power radiated from a jet varies with the jet velocity raised to the

eighth power for velocities up to 600 m/s (2,000 ft/s) and varies

with the velocity cubed above 600 m/s (2,000 ft/s). Thus, the lower

speed exhaust jets emitted from engines such as high bypass turbofans are the

quietest, whereas the fastest jets, such as rockets, turbojets, and ramjets,

are the loudest. For commercial jet aircraft the jet noise has reduced from the

turbojet through bypass engines to turbofans as a result of a progressive

reduction in propelling jet velocities. For example, the JT8D, a bypass engine,

has a jet velocity of 400 m/s (1,450 ft/s) whereas the JT9D, a

turbofan, has jet velocities of 300 m/s (885 ft/s) (cold) and

400 m/s (1,190 ft/s)(hot). The advent of the turbofan replaced the

very distinctive jet noise with another sound known as "buzz saw"

noise. The origin is the shockwaves originating at the supersonic fan blade tip

at takeoff thrust.

Cooling

Adequate heat transfer away from

the working parts of the jet engine is critical to maintaining strength of

engine materials and ensuring long life for the engine. After 2016, research is

ongoing in the development of transpiration cooling techniques to jet

engine components.

Operation

Airbus A340-300 Electronic

centralised aircraft monitor (ECAM) Display

In a jet engine, each major

rotating section usually has a separate gauge devoted to monitoring its speed

of rotation. Depending on the make and model, a jet engine may have an N1 gauge

that monitors the low-pressure compressor section and/or fan speed in turbofan

engines. The gas generator section may be monitored by an N2 gauge,

while triple spool engines may have an N3 gauge as well. Each

engine section rotates at many thousands RPM. Their gauges therefore are

calibrated in percent of a nominal speed rather than actual RPM, for ease of

display and interpretation.

What Is a Jet Engine? Evolution of Jet Engine

ReplyDelete